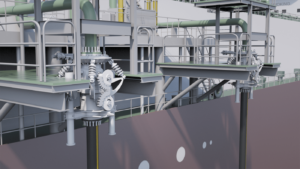

INTEGRATED HPNG ERS OFFSHORE

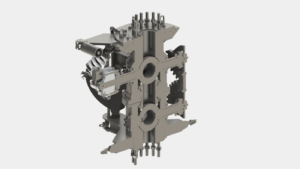

The Integrated Emergency Release System (ERS) is the heart of the HPNG Package.

It includes dual ball valves which can be used to isolate each manifold/flexible hose and that are secured together by a hydraulically activated internal Emergency Release Coupler (QCDC).

The purpose of this system is to provide protection of the installation, the operating staff, and the environment by isolating the product flow and providing rapid release under extreme or emergency situations during the HPNG transfer.

The ball valves are fitted with spring and pressure energised seat assemblies which ensure positive shut-off at high and low pressures.

The ERS assembly is provided with a blow-down system to depressurize and vent the HPNG entrapped between the ball valves cavity after an ESD sequence is triggered and the ball valves of the ERS are closed.

Being this a critical continuous service application, the ERS architecture is compliant with SIL2 requirements.

The lower hose side valve is fitted with two lifting arms complete with shackles, extending diametrically opposite to each other. The arms contain the pull-in pad eyes and shackles for connection of the hose winch.

A typical solution includes a dual post (mounted on the lifting arms) and funnel guidance system (mounted on the skid structure) but other options can be considered.

Reconnection requires the two halves of the unit to be engaged. The winching and guidance system provided will control the initial mating of the two halves. Once the two halves are engaged final radial alignment is assured by the conical shape of the mating surfaces.

- Design Pressure

Up to 10.000 psi - Design Temperature

Ambient - Size

4″ to 20″

- Handled Product

High Pressure Natural Gas