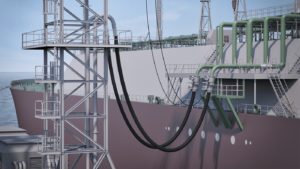

HPNG SHIP TO JETTY

This transfer system has been developed to deliver high pressure natural gas from a permanently moored FSRU vessel to shore, by means of high pressure jumper hoses.

The system includes the following main equipment:

- Emergency Release Systems (ERS) c/w hydraulic power and control pack;

- High Pressure Jumper Hoses;

- Jetty Support Tower for Jumper Hoses c/w Retaining Sling;

- Electro-hydraulic aerial umbilical;

The following advantages of the jumper hose system transfer versus other traditional installations are identified:

- Optimisation of CAPEX investment;

- Significant reduction in weight. This will positively reflect on the jetty construction/modification itself;

- No major jetty modifications or special foundations are required;

- Significant reduction in costs and time for installation. Unlikely for the need for floating cranes, heavy lifting gear, etc.;

- No need for scaffolding or removal of the equipment to an off-site area for servicing; hence reduced down time;

- Reduced number of potential leak paths;

- Lower overall shipping cost to site. The jetty tower is suitable to be containerized and as an alternative, could be also built locally;

- The hose system does not involve any requirement for hydraulic power, except for the ERS which in any case requires hydraulic power only in case of an emergency release;

- The hoses and the jetty structure do not require any maintenance during normal operation and eliminates the nedd for any moving part such as swivels, bearings, hydraulic cylinders, etc. normally associated with other types of transfer solutions;

- The lead time for a complete system is significantly low; this being particularly important for many FSRU projects which are often time-driven;

- Reduction in OPEX cost for spare parts and intervention activities;

- Part of the scope (integration of the ERS with relevant power and control system) is typically installed at the vessel coversion stage (e.g. shipyards), thus reducing further the activities to be held at site when FSRU arrives.

To suit the vessel motions and ensure safe transfer within a wide drift operational envelope, a project specific catenary configuration is studied by MIB in order to cater for extreme cases. As well as static and dynamic analyses are performed to calculate the loads exerted on the jetty structure and on the jumper hoses in the extreme load case scenarios including the release.